STOCK NOTICE: PRINTBITE is currently out of stock!

PrintBite+ is the only 3D Printing Surface you will ever need! Offering great value with superior performance!

PrintBite+ is a premium 3D Printing Surface that offers great value and performance, providing strong adhesion whilst printing, and releases as the bed cools down. No need for adhesion substrates such as gluestick, ABS paste/juice/slurry etc. Printing onto PrintBite+ is as easy as pressing “print”. Once your print has completed and the bed has cooled the parts will self release allowing you to remove them by simply picking them up. No more forcing parts off the buildplate or using scrapers. No risk of personal injury nor damage to even the most delicate prints.

Please use the option boxes to configure your requirements.

Click here to download instructions

No matter the Material! TPU, TPE, PLA, PETG, ABS, Nylon, PC, NinjaFlex, FilaFlex, PolyFlex, Woodlay, ASA, Taulman Range filaments and many others, PrintBite+ supports them.

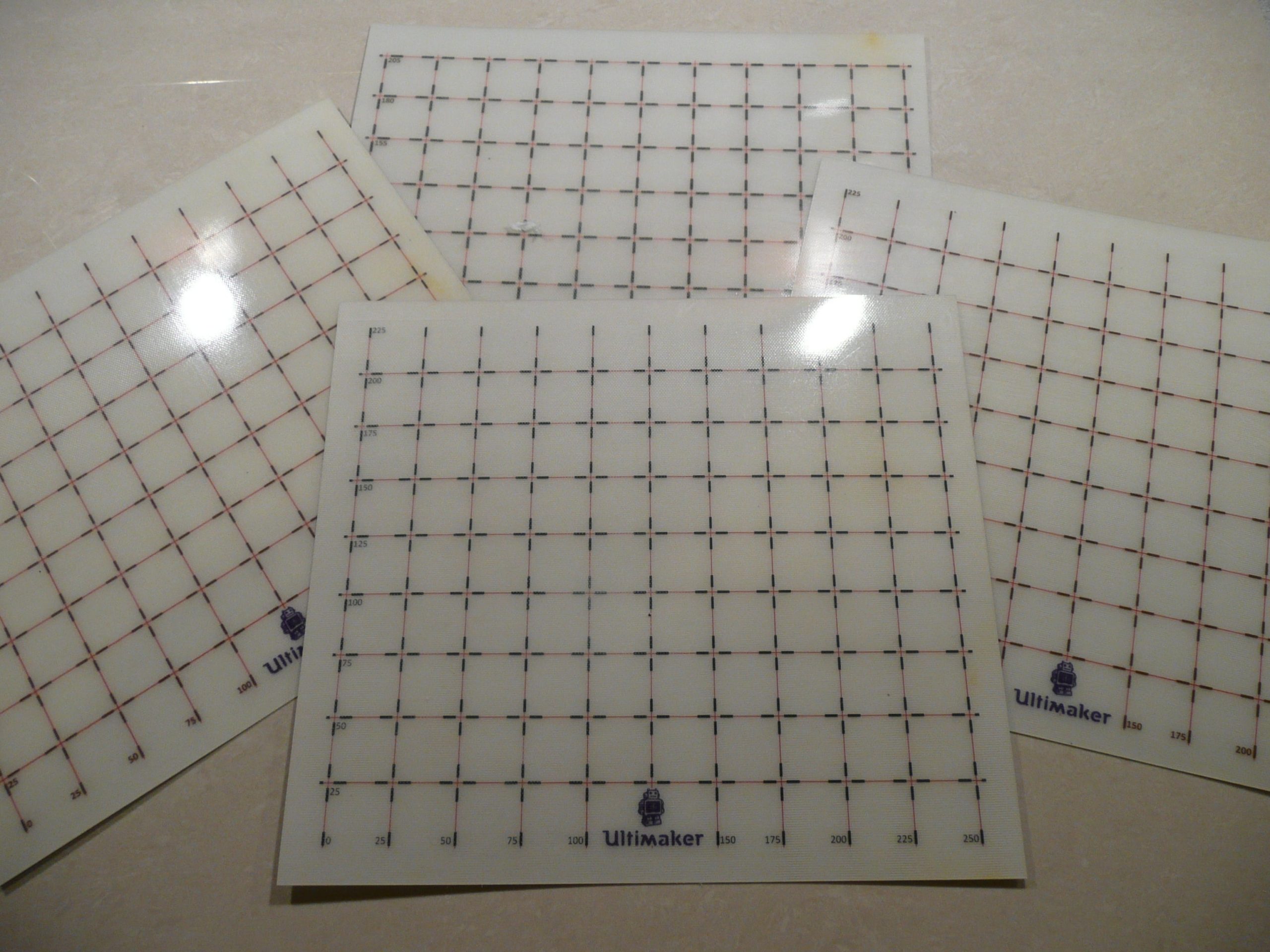

Choose from BLACK or CLEAR colour, with Matte or Gloss finish. Comes with high temperature adhesive backing. Clear PrintBite comes with a grid graphic applied or we can add your own custom graphic for you. These options will give your machine a nice professional customized finish. NOTE: Black PrintBite is supplied plain only.

PrintBite+ has a thickness of 0.4mm making it suitable for use with all printers and all bed levelling sensing methods including PINDA IR Piezo Inductive Capacitive.

PrintBite+ ships wrapped in a zip lock bag or acid free tissue paper, inside a board backed envelope. Double cardboard in a post bag for the larger sizes.

To keep costs and prices as low as possible we carry a range of standard sizes. For other sizes please select the nearest size that your required dimensions will fit into, and add a note when checking out. We will then cut to size at no charge.

Note: If selecting Black, please select “plain” in the graphic drop down menu. Please contact us first if you require gloss black. Thank you.

thecoolkids322 (verified owner) –

Originally I used liquid glue slurry for my bed adhesion and I thought it worked great, boy was I wrong. I had to reapply it often and corners lifted on big prints. I then tried out printbite. When I opened the package it was stiffer than I expected. I knew this was quality stuff. Not once have I had a corner lift no matter what I print. I leveled my bed with a piece of paper and did a negative z offset of 0.05mm. I also did 65c first layer pla and 60 degrees so on. My extruder temps were 195 first layer 190 other layers. With these settings printbite worked like a charm and the parts came off easily with no tools and no failed prints. Just remember to wipe with acetone anytime you touch it. I got my acetone from menards branded sunnyside and it works great,

alex (verified owner) –

I thought I didn’t need this. I was using PEI for years and thought it was fine. But wow was I wrong. So far, it’s worked perfectly every single time.

davidjericho (verified owner) –

I’ve been printing PETG exclusively on PrintBite+ after installing it, and the performance is incredible.

Get the first layer down, and while the bed is hot the print sticks like nothing else. Let the bed cool, and the print self detaches, allowing me to pick it up with absolutely no effort. I literally mean no effort. Walk up, pick it off the bed, as if I were picking the same object off from my desk or the floor or my hand.

The bottom finish is clean and of high quality, and cleaning the bed itself is very simple.

I’ll be putting PrintBite+ on all my other printers too!

contact3 (verified owner) –

Very good product for many materials.

All my printers are with printbite!

Nathan Foster (verified owner) –

Just bought it for my third printer. Having used a plethora of other build surfaces nothing quite comes close.

Graeme (verified owner) –

I have no words! Your prints go suddenly from average to perfect by using PrintBrite. I wished I purchased this product earlier to save on the numerous frustrations of wrecking my build plate.

gueee78 (verified owner) –

I recently purchased PrintBite plus for my Ender 3, first of all I’d like to say thanks for the custom cut.

I absolutely love it, it does everything as promised and I tested nearly everything, even genuine Buildtak and their PEI sheets don’t come close to the performance of PrintBite!

I’m going to purchase it for all my printers now.

dancem (verified owner) –

Best surface I ever tried. I use it for several months. Filament stick well, prints removes easily on cold (or even while hot, just use IPA on print edges during removal) and have nice mate surfaces. Order processing was pretty long, but it worth this waiting. You should be careful with the surface (do not use any metal tools for prints removal) and keep it clean (with IPA). But again, that is THE BEST. I will definitely order more for my next printers.

brixkramme (verified owner) –

Best printing surface I have tryed. Its bond to the surface and after cooling its very easy to remove.

ocward (verified owner) –

I have bought Printbite+ for every printer I have owned over the past few years. It is unquestionably my favorite printing surface. It is especially great for PETG, which sticks very well while printing, yet releases easily when the bed cools. It also works well for Flexible materials – print with no bed heat and then peel off the print after its complete. Of course it also works perfectly for PLA and ABS. I do wish it was a bit cheaper, especially considering the shipping to the US, but I suppose it is priced fairly, since I continue to buy it for every printer 🙂 I have never needed to replace a sheet, so the price per life is actually quite low. Printbite+ essentially eliminates the benefit of a removable flex plate like on the Prusa MK3. I have this on my removable flexplate and I never need to remove it.

BenD188 (verified owner) –

This is a game changer. After cooling my prints just lift off the bed without needing to use any tools! No more struggling with spatulas or pliers. Heating the bed an extra 5-10 degrees is perfect. So far I’ve tested with PLA and PETG and had great results. This is a must have!

Jason Perkes –

Hi BenD188, thank you for the review, and great to hear your satisfaction with our product.

joe (verified owner) –

I just received a PrintBite sheet for my Ender 3 and in spite of my skepticism it’s absolutely awesome. You must follow the instructions for applying it to your bed or glass panel, but once that’s done it will change the way you use your printer. Whereas I used to watch the printer until it was well into the print, now I simply press the print button and walk away. I have never had a print fail or lift off the bed since I bought the PrintBite sheet. In fact I am now so confident I print multiple copies and leave the printer run overnight, I would not have dared to do that before.

brian.aldred (verified owner) –

Just a superb product. I got mine for the CR-10, so 300×300.

Follow the instructions and you can’t go wrong.

I’ve printed things as large as 200x180mm with full contact to the print bed across that area (i.e. bottom of a paints holder I wanted/needed) and once cooled I literally just pick it up off the bed. At the other end of things, I’ve printed the internal core for a Harry Potter wand which was only about 5mm diameter contact area but was about 100mm tall. When the bed cooled down it fell over – I guess from some minuscule breeze.

Previously I used a buildtak-like surface and whilst they give great adhesion I’ve lost track of the number of damaged prints among other issues (it sticks just too well mostly). With this printbite I’ve got no marks/dents/gouges or stuck-on residue after a lot of prints already. It just prints and comes off easy afterwards.

Certainly it’s more expensive than alternatives but truly the price is justified.

I CAN’T RECOMMEND THIS ENOUGH.

mitchhd2020 (verified owner) –

I recently took the gamble on trying printbite, tired of abs slurry and glue sticks and the mess that goes with it not to mention that adding adhesives changes the accuracy of the bed level. So I applied it as per instructions and it’s freaking awesome does what it says which was a Pure delight as I print mainly with abs and this stuff sticks as good as any adhesives used. (or better) Definitely recommend it I will be purchasing a second sheet for my other Tevo Little Monster now I know it works.

Good product guys / girls

Five stars 🌟🌟🌟🌟🌟

joepwelling (verified owner) –

More than perfect bed surface,works perfect on a flexible steel plate on my Felix Tec 4

Matt surface gives a beautiful bottom layer.

The effect is rely nice to see when you take the steel plate of the heated bed base plate and put it on a cold table-top first you can lift the part white plate but as soon as cold-down you only lift the printed part.

I like it very much!

phil.wilson25 (verified owner) –

I cynically thought that this wouldn’t work as well as advertised, but it really does! I had lifting problems with ASA and the usual ABS juice, but PrintBite solved it brilliantly. Excellent, because I hate messing around with ABS juice. You don’t even need to print a brim. PLA predictably works perfectly, as does TPU. Follow the instructions with each material on this site. Prints lift off when cooled so easily it doesn’t quite seem real. The PrintBite sheet was easily applied to my glass sheet as described in the instructions. I bought the smooth black sheet, and it looks very smart. PriteBite is magic, and should be worshipped 🙂

Jason Perkes –

Not much I can respond with, but to say Thank You for your review.

Anonymous –

Can you make a 345×520 sheet? I would like this for my Stacker S4 machine, I have 2, but I know other people would like them.

Jason Perkes –

Hi there yes we can. Please contact us directly by email or contact form and we can arrange this for you.

markferrick (verified owner) –

that I would ever get the product. I ordered around Thanksgiving and after a few delays I finally received it. Thank you for the extra gift for my troubles. Now I installed the smooth surface and installation was trouble free. A quick cleaning with acetone ( used JASCO Acetone (MDS says 100% pure) started printing.

now after 2 months of using it I am thrilled. Prints are smooth as silk on the bottom, filament ( PLA and PETG ) sticks great when being printed on 50*C bed. I still get a kick when the bed goes below 30*C, the prints lift right off. No more putty knife, vise grips, struggling to remove the print.

Bottom Line, I love it. Great investment.

richgain (verified owner) –

Undoubtedly the best print surface I have found in 7 years of 3D printing. It’s the first thing I fit on all my printers.

Jason Perkes –

Excellent thank you for the great comment. Glad to hear you like it. BTW loving those AWESOME puzzles.

axel.wilkin –

I would like to know if nylon adheres on the printbite?

Can we stick the printbite on a sheet of aluminum?

Jason Perkes –

Hi Yes Nylon will adhere to PrintBite, depending on the brand, 100-120c will be required. Yes you can also adhere PrintBite to Aluminium sheet or cast tooling plate, but please ensure if using ali sheet, that it is perfectly flat.